WE ARE YOUR STRATEGIC PARTNER in the

Gulf of Mexico

Located in the heart of the Gulf of Mexico, our privileged location offers a number of unparalleled benefits for your maritime projects.Hutchison Ports TNG is located near offshore oil and gas probes, as well as of the most important communication routes that connect the southeast of the United States, the Caribbean and Mexico.

We are prepared to meet the most demanding needs of the naval industry. Our shipyard in Veracruz is the ideal meeting point between the logistical efficiency and technical excellence.

We take care of your boat and we take care of you. Our team is dedicated to providing personalized attention and finding solutions that allow you to feel supported at all times. Quote your project

AGILITY IN THE REPAIR OF YOUR BOAT

Hutchison Ports TNG has a team of professionals in rope access technology, specialized in the needs of the naval industry.

Through rope access we offer greater flexibility and abilityto work in areas of difficult access, minimizing time and guaranteeing efficient, safe and high-quality work.

NAVAL CONVERSION

We transform and adapt your fleet to the latest technological innovations to comply with the requirements of safety, environment and new maritime regulations.

We work in alliance with our customers putting at your disposal a great team of engineers and certified labor to carry out conversions tailored to your needs.

WE MEET THE MOST DEMANDING NEEDS OF THE NAVAL INDUSTRY

WE GUARANTEE QUALITY AND SAFETY IN EACH PROJECT, BACKED BY MORE THAN 28 YEARS OF EXPERIENCE IN THE MARITIME SECTOR.

We coordinate the import not only of the boat but also of the spare parts, spare parts and materials required, including prior to the arrival of the vessel or naval device to our shipyard, reducing costs and times.

Our foreign customers have the full support of TNG for the temporary importation of their vessel without paying import taxes. foreign trade, with the purpose of proving legal stay and possession in national territory.

We take care at all times to comply with Mexican Customs Legislation, while we guarantee that our customers have their materials on time for their work. repair and maintenance.

Hutchison Ports TNG is considered a Highly Exporting Company of Services by the Federal Government, which gives us prestige and seriousness before the customs and tax authorities.

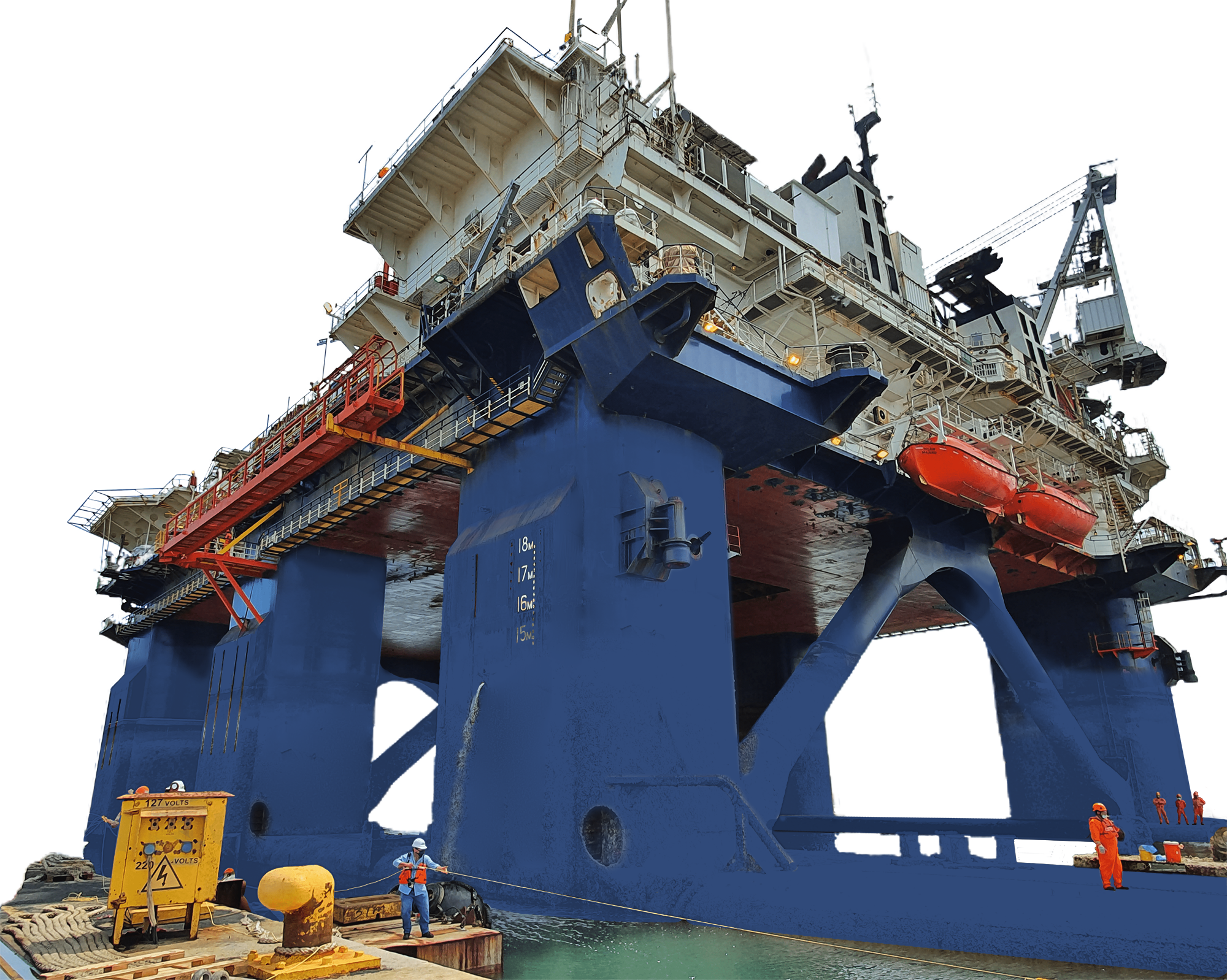

PLATFORM REPAIR

We offer solutions that guarantee the structural integrity and safe operation of your platform at all times.

Trust TNG with the maintenance or repair of your platform and operate with total safety and efficiency on the high seas.

WE TAKE CARE OF YOUR BOAT

DOWN TO THE LAST DETAIL

From planning to precise lifts to the installation of large-scale structures, our expert marine engineering engineers ensure the flawless execution of repair and construction projects, naval conversion, as well as metal-mechanical fabrication. Our Engineering department is made up of a team specialized and experienced in naval engineering analysis and cutting-edge structural calculations.

WE CONQUER NOT ONLY THE SEA, BUT ALSO THE LAND

From conceptual design to final installation, we are your partner in creating high-quality light and heavy structures. We adapt to the regulations that your project requires: AWS, ASME, API, PEMEX, ISO, AISC, IMCA.

The quality of the machining processes offered by Hutchison Ports TNG allows us to satisfy the diverse needs of our customers, such as the grinding of winch components, machining of propellers, machining of bushings for propulsion system horns and government system.

Our machining services are complemented by an engineering department, rolling workshop, plasma cutting machines and certified welding procedures to offer high precision and speed.

In the scrapping service our engineers design the scrapping program for vessels up to 200m in length, by cutting blocks weighing up to 60 tons, through precise analysis and calculations that allow us to ensure the integrity of the vessel while it is afloat.

We have maneuvering personnel and crane operators who are experts in lifting. The handling and disposal of waste is carried out in accordance with environmental standards.

In compliance with the ISO 8501 standard, we clean and paint steel plates and profiles with metal shot, with an anchor profile of 63 microns, and apply weldable workshop primer with a resistance of up to 6 months to the elements.

Likewise, at TNG we provide plate cutting services with numerical control pantographs, enabled with plasma to cut stainless steel or aluminum, and oxy-fuel cutting for stainless steel plates. coal, in thicknesses of 25 to 150 millimeters.

From the curvature of hull plates to the formation of complex structures, our rolling service is capable of addressing a wide range of requirements, adapting to the specific needs of each project, whether naval or industrial.

Each rolling job is carried out according to the API 2B standard or according to the customer's requirement and with certified welding procedures.

Hutchison Ports TNG has more than 25 years of experience in professional non-destructive examination service. Our engineers are certified by the American Association for Nondestructive Testing (ASNT).

The repair Naval industry demands thickness measurement, weld exploration by ultrasonic means, calibration services and fault detection. To this end, our team performs visual inspections and tests of: ultrasound, magnetic particles, penetrating liquids and X-rays.

Hutchison Ports TNG has the qualified technical personnel, machinery and instruments necessary to carry out the diagnosis-analysis of vibration and balancing of equipment as well as the flushing and filtering of Hydraulic lines, in order to prevent or correct behavior, of our customers' machinery.